The Role of Wireless Systems in Factories

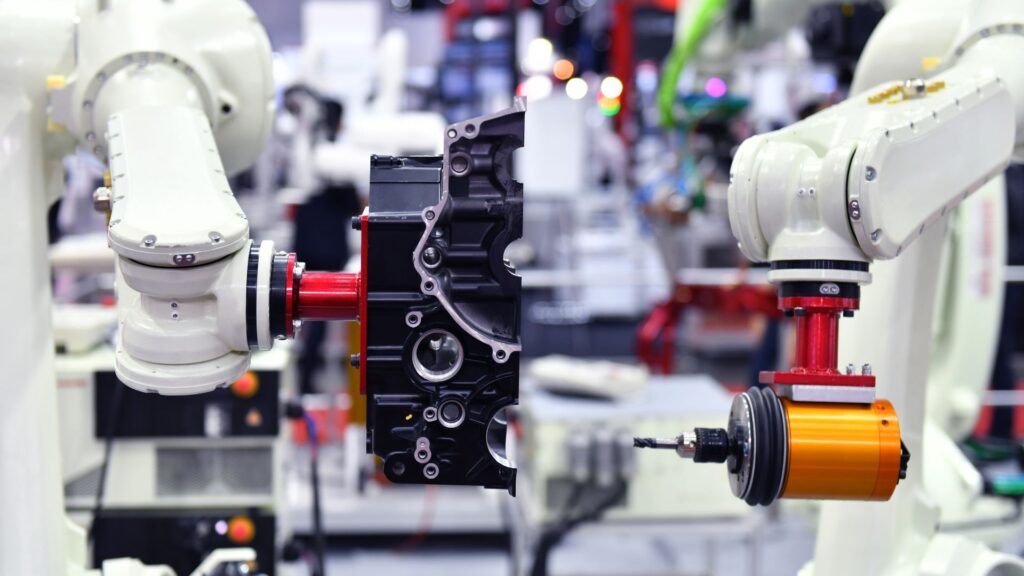

The integration of wireless systems in factories represents a transformative leap towards smarter, more efficient manufacturing. In the ever-evolving landscape of manufacturing, technological advancements continue to reshape traditional processes.

This paradigm shift has not only improved operational efficiency but has also paved the way for smarter, more agile manufacturing environments.

Wireless Connectivity: The Backbone of Industry 4.0

The fourth industrial revolution, often termed Industry 4.0, emphasizes the seamless integration of digital technologies into manufacturing processes. Wireless systems play a pivotal role in achieving this integration by providing reliable and high-speed connectivity. From sensors and actuators to production machinery, the entire factory floor becomes a networked ecosystem, facilitating real-time data exchange.

Internet of Things (IoT) and Sensor Networks

Wireless systems enable the widespread implementation of IoT devices and sensor networks in factories. These sensors collect valuable data on machinery performance, energy consumption, and production output. Through wireless connectivity, this data is transmitted to centralized control systems, empowering manufacturers to make informed decisions and optimize production processes.

Enhanced Mobility and Flexibility

Traditional wired systems often limit the mobility of machinery and production equipment. The adoption of wireless systems liberates these components, allowing for greater flexibility in factory layout and reconfiguration. This enhanced mobility promotes agile manufacturing practices, enabling factories to adapt quickly to changing production requirements.

Real-time Monitoring and Control

Wireless systems facilitate real-time monitoring and control of various manufacturing parameters. Whether it’s monitoring the temperature of a machine or adjusting production speeds remotely, wireless connectivity empowers manufacturers to respond promptly to potential issues and optimize processes on the fly.

Predictive Maintenance

Predictive maintenance is a critical aspect of modern manufacturing, and wireless systems play a crucial role in its implementation. By continuously monitoring the condition of machinery through sensors, these systems can predict potential failures and schedule maintenance activities proactively. This not only reduces downtime but also extends the lifespan of equipment.

Data Security and Integration

As factories become more interconnected, the issue of data security becomes paramount. Wireless systems are designed with robust security protocols to safeguard sensitive information. Moreover, these systems facilitate seamless integration with other digital technologies, such as cloud computing and big data analytics, enhancing the overall efficiency of the manufacturing process.

Cost-effectiveness and Scalability

The deployment of wireless systems in factories often proves more cost-effective than traditional wired alternatives. The absence of physical cables reduces installation costs and maintenance efforts. Additionally, wireless systems are highly scalable, allowing manufacturers to expand their digital infrastructure as needed without the constraints imposed by physical wiring.

Get the Right Team

It takes skill and expertise to ensure that that your wireless system functions optimally. Vivo Asia is a team of expert engineers, technicians and drafters who are well versed in industry compliances and have over 10 years of experience in integrating and upgrading wireless systems.