Wifi Coverage Studies for FPSO Vessels

Industries are increasingly adopting technology and digitizing their operations, content and processes.

The oil & gas industry, which is known to be very conservative in adopting new tech, has recently started to move faster in their digitization journey, in view of potential risks they may face to the safe operation of facilities.

The journey has been well complemented by industry players such as equipment manufacturers, testing and accreditation agencies and by consultants. One area we see a big change is the way Wi-fi technology is making its way into the process areas of FPSOs and other oil & gas facilities.

In the past wi-fi coverage was limited to the living quarters of FPSOs and process platforms as the usage of explosion proof mobile devices was not that popular. As of late, almost all FPSO projects that are under construction or being retrofitted are fitted with explosion proof wi-fi access points which allows operation and maintenance staff to use mobile devices for increased efficiency of their job.

This transformation does not come easily as there are challenges in providing a good wi-fi coverage for a topside modules on an FPSO. We are taking an FPSO as an example but it’s important to note that a process platform or a drilling rig will not differ too much in the way they need to be covered by wi-fi.

Case Study

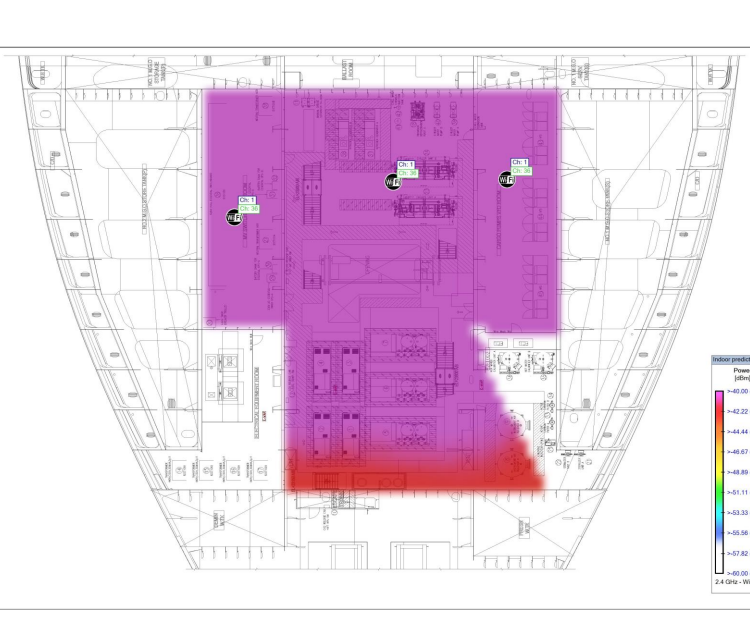

Vivo Asia has been providing solutions mainly for FPSOs to have sufficient wi-fi coverage for in the topside module areas. After careful assessment of the requirements and conducting a coverage study, explosion proof wi-fi access points are placed strategically on the main deck and process decks of different modules to allow personnel working in these areas have a sufficient level of signal strength to get a good wi-fi connection.

It must be noted that this study was conducted purely to verify the signal strength the software used by Vivo Asia has the capability to do capacity and channel planning as well. A large number of users is not expected in these areas and the priority is given to verify coverage rather than the capacity and traffic planning. However, if required the channel allocation and capacity planning can also be done using the same software that simulates the coverage.

Get the Right Team

Contact Vivo Asia for planning the coverage and adding explosion proof wi-fi access points for your project!

We specialize in providing engineering solutions to harsh and hazardous industries. Our engineers are trained in using state of the art simulation software as well as ensuring strict compliance to safety standards required.

Our engineers’ experience combined with project management skills ensures information is disseminated effectively and we are able to support both new-build and upgrade projects to complete within budget and time.